Table of Contents

ToggleLet’s take a deep dive into the Japan manufacturing industry

From the sleek assembly lines of automotive giants to the precise craft of electronics manufacturing, Japan’s industrial landscape is a testament to the country’s unwavering commitment to quality, efficiency, and innovation. As the fourth largest economy in the world, Japan’s manufacturing sector remains a powerhouse, combining centuries-old traditions with cutting-edge technologies. This comprehensive blog post is your gateway into the heart of Japan’s manufacturing world, providing insights into its historical evolution, current state, unique challenges, success stories, and a glimpse at what the future holds.

Introduction to Japan Manufacturing’s Prowess

The Japan manufacturing industry has left an indelible mark on the global economy, synonymous with the highest standards of production and the birthplace of some of the most influential management and operational philosophies. From the precision of a Tachi sword forged in ancient Japan to the just-in-time models pioneered in the 1970s by companies like Toyota, Japanese manufacturing has redefined standards across centuries.

The country’s post-war recovery through manufacturing innovation has become a benchmark for economic revival, leading to the period’s nickname “Japanese Economic Miracle.” Let’s peel back the layers of Japan’s robust manufacturing sector to understand the magic that propels it forward.

Read more: Japan Agriculture: A Sustainable Approach

Evolution of the Japan Manufacturing Industry

Post-WWII Reconstruction and Kaizen Philosophy

Emerging from the ashes of World War II, the Japan manufacturing sector underwent a dramatic transformation. The post-war environment necessitated a focus on efficiency, speed, and resource conservation, giving birth to the renowned ‘kaizen’ philosophy, which means continuous improvement. This ethos of quality control became the cornerstone of Japan’s manufacturing culture and laid the groundwork for future success.

Lean Manufacturing Principles Adoption

Closely linked to kaizen is the concept of lean manufacturing, which aims to eliminate waste and improve overall efficiency. Among the first to adopt these principles, Japanese companies quickly realized the competitive advantage they offered. By the 1970s and 1980s, Japan had cemented its status as an industrial powerhouse, with companies like Toyota and Honda leading the charge.

Technological Advancements

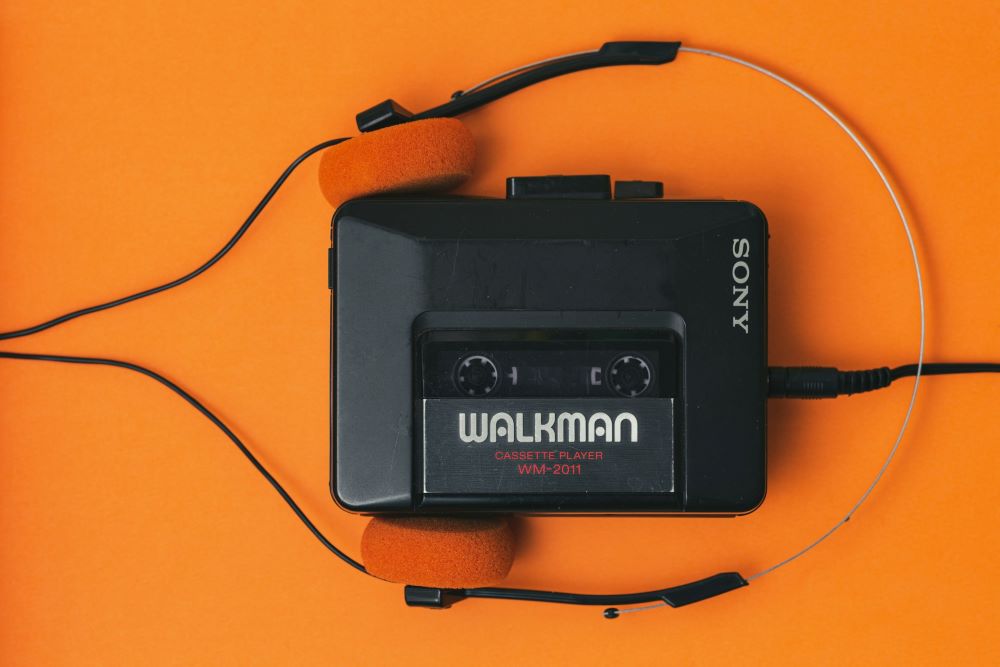

The 1980s and 1990s saw Japan embracing technological advances, further solidifying its position in global manufacturing. Innovations in robotics, automation, and precision engineering set new benchmarks for the industry. The emergence of high-tech consumer electronics, such as the Walkman, invented by Japanese company Sony in 1979 and introduced internationally in 1980, as well as the videotape format war between Sony’s Betamax and fellow Japanese company JVC’s VHS, showcased Japan’s prowess in delivering products that captivated the global consumer market.

Current State of the Japan Manufacturing Industry

Global Market Position

Japan continues to be a major player in global manufacturing, with significant market share across various industries. The automotive, electronics, and machinery sectors stand out as pillars, with products renowned for their durability and innovation.

Innovation and Sustainability Efforts

Amid global calls for sustainability, Japan’s manufacturers are not only leveraging technology to create more efficient processes but are also pioneering new materials and product designs. From solar panels to electric vehicles, Japan’s commitment to a greener planet is driving innovation within the industry, setting it on a path towards sustainable manufacturing practices.

Read more: Japan’s Renewable Energy Sector: A Quick And Balanced Look On A Rising Industry

Challenges Faced by Japan’s Manufacturers

Despite its formidable reputation, the Japan manufacturing sector is not immune to challenges. An aging population presents a significant hurdle, with the workforce shrinking and the manufacturing talent pool diminishing. Furthermore, increasing competition from emerging markets and the disruptive force of new technologies require Japanese manufacturers to adapt swiftly to remain competitive.

Read more: Manufacturing in Vietnam: An Unexplored Goldmine for Global Investors

Success Stories and Innovations in Japan’s Manufacturing

Leading Japanese Companies

Japan is home to some of the world’s most recognizable manufacturing companies, including Sony, Mitsubishi, and Panasonic. These corporate giants have not only shaped the global market but have also contributed to the nation’s identity as a center for technological progress.

Breakthrough Technologies and Practices

Japanese manufacturers are relentless in their pursuit of cutting-edge technologies. The country consistently ranks among the top for patent registrations, fueling a culture of innovation within the industry. Furthermore, the adoption of Industry 4.0 concepts, such as the Internet of Things (IoT) and artificial intelligence, is transforming traditional manufacturing.

The Future Outlook for Japan’s Manufacturers

Industry Trends and Predictions

The coming years will likely see Japan’s manufacturing sector focus on diversification and specialization. With increasing consumer demand for customized products, Japanese companies are exploring new ways to differentiate themselves. Additionally, the integration of digital technologies is expected to lead to more flexible and responsive manufacturing capabilities.

Potential Strategies for Sustained Growth

To address the challenges ahead and ensure sustained growth, Japanese manufacturers are turning to a variety of strategies. These include upskilling the existing workforce, encouraging entrepreneurship and start-ups, and fostering closer collaboration between the public and private sectors to drive innovation and policy reform.

The Resilience and Adaptability of Japan Manufacturing

In conclusion, the Japan manufacturing industry stands as a testament to resilience and adaptability. Despite facing challenges, Japan continues to set benchmarks for operational excellence, innovative products, and sustainable business practices. As we look to the future, it’s clear that the harmonious blend of tradition and technology will keep Japan at the forefront of global manufacturing.

For those seeking to be part of this industry’s vibrant ecosystem, it’s an exciting time to consider a foothold in the Japanese market. As you chart your course, remember that understanding the local business environment, including regulations, culture, and market nuances, is critical to your success.

If you’re ready to take the first step, consider Eos’ Employer of Record services with our over 15 years of experience in the Japanese market to expedite your entry into the Japanese manufacturing landscape, ensuring a smooth and compliant operation from the start.

Contact Eos Global Expansion today. Check our services here or book a free consultation now.

Featured photo by ayumi kubo on Unsplash